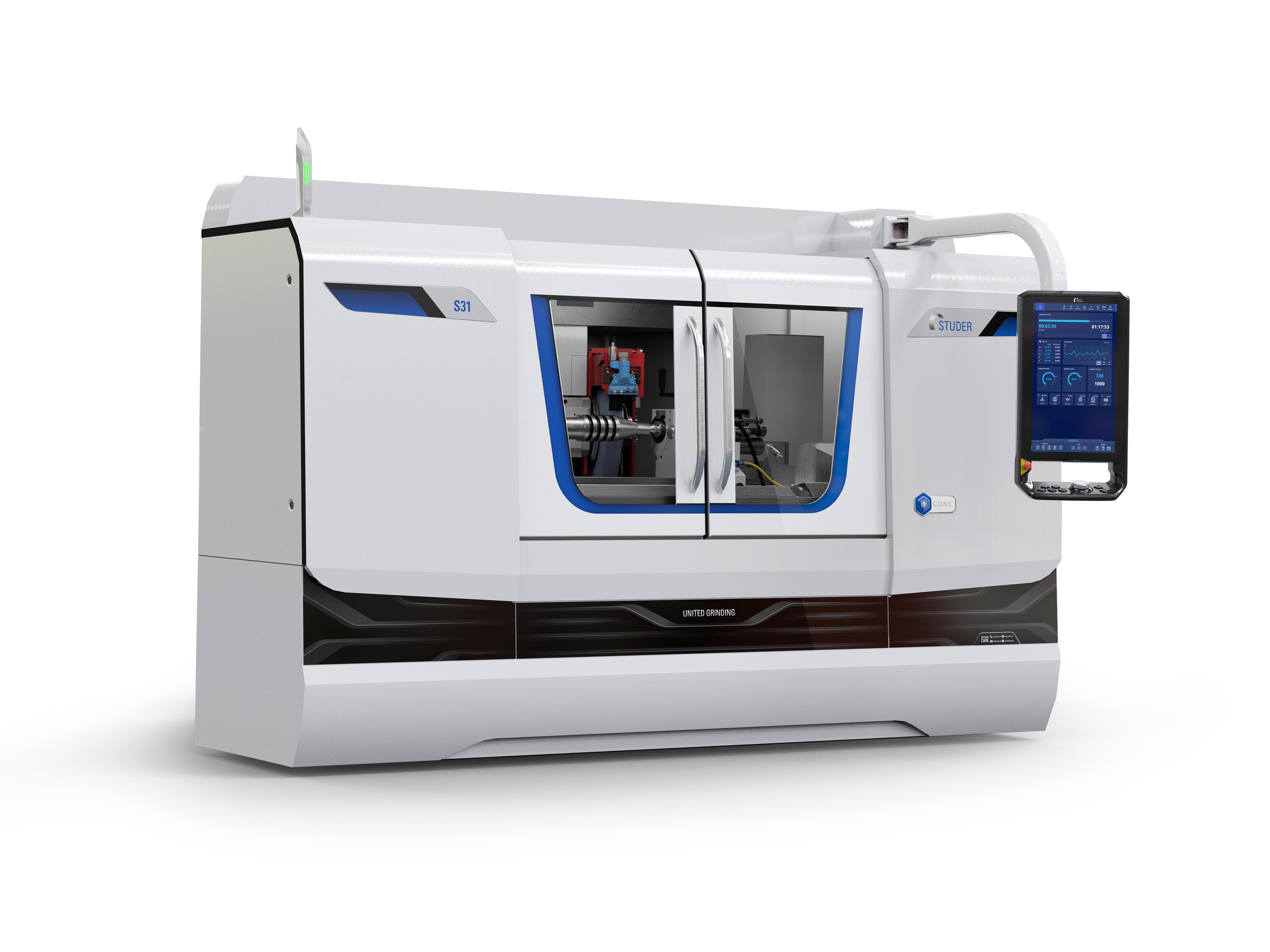

斯图特 S31

展商:United Grinding Group Management AG

原产国/地区:瑞士

S31是一款适用于小尺寸到大尺寸工件的数控万能内外圆磨床,同时支持单件加工,小批量和大批量生产。其具备400/650/1000/1600mm的顶尖距和175mm的中心高度。工件最大加工重量为150kg。S31采用可扩展模块化系统, 可以充分涵盖您的需求。配备了0.00005°高分辨率的砂轮头架旋转B轴, 配置高精度C轴,实现高速非圆及螺纹磨削,机床床身采用坚固的Granitan®S103人造花岗岩材质,导轨采用Studer专利静动压集成导轨。非圆磨削在Capto磨削领域有着大量的应用,机床可一次装夹即可完成外圆、内圆和端面磨削,S31在机床主轴,刀具, 航空航天,模具等精密加工需求领域有着广泛应用。 The S31 is a cylindrical grinding machine for small to large workpieces in single, small and large series production. It has a distance between centres of 400mm (15.7") / 650mm (25.6") / 1,000mm (40") / 1,600mm (63") and a centre height of 175mm (6.9"). It can machine workpieces with a maximum weight of 150kg (330lbs).Thanks to the upgradeable modular system, the S31 can be adapted to match your precise requirements. The swiveling wheelhead allows you to externally, internally and face grind workpieces in a single clamping – with a high-resolution B-axis of 0.00005°. Configuring high-precision C-axis to achieve high-speed non-circular and thread grinding. Non-circular grinding has a large number of applications in the field of Capto grinding. Machine tools can complete external, internal, and end-face grinding with just one clamping. S31 is widely used in precision machining fields such as machine tool spindles, cutting tools, aerospace, molds, and so on.

展品详情

硬件部分:

· 转塔式砂轮主轴可选装:

-无级分度B轴,力矩电机

-1°分度B轴,端齿盘定位

· 变频控制的磨削电主轴,适用于内外圆磨削

· 工件头架主轴配备C轴,可用于非圆和螺纹磨削

· C.O.R.E.面板

· 工作台集成双T型槽,可用于安装修整设备

· 全封闭外罩带双滑动门

· Granitan®S103人造花岗岩床身

软件部分:

· C.O.R.E. OS操作系统

· 采用StuderPictogramming图标编程,编程简单方便

· STUDER QuickSetk快速对刀软件可帮助减少设置和转换时间

· 高速加工 (HSM),帮助实现高效、高精度的非圆磨削

· 加料装置和外设均采用标准化接口

· 集成软件模块,可灵活进行扩展

· 提供StuderWINprogramming软件(可选),支持在外部计算机上创建磨削和修整程序

Hardware:

· Turret wheelhead with the option of:

– Stepless B axis

– B axis with 1° Hirth serration

· Frequency-controlled motor-driven grinding spindles for external and internal grinding

· C-axis for the workhead for form and thread grinding

· C.O.R.E. Panel

· Tool table with integrated double T-slot for dressing devices

· Full enclosure with two sliding doors

· Granitan® S103 mineral casting machine base

Software:

· C.O.R.E. OS Operating system

· Very simple programming thanks to Studer- Pictogramming

· Reduced setup and resetting times with STUDER QuickSet

· High-speed machining (HSM) for efficient and high-precision form grinding

· Standardized interfaces for loader and peripheral devices

· Flexibly expandable with integrated software modules

· StuderWIN programming software (optional) for creating grinding and dressing programs on an external PC