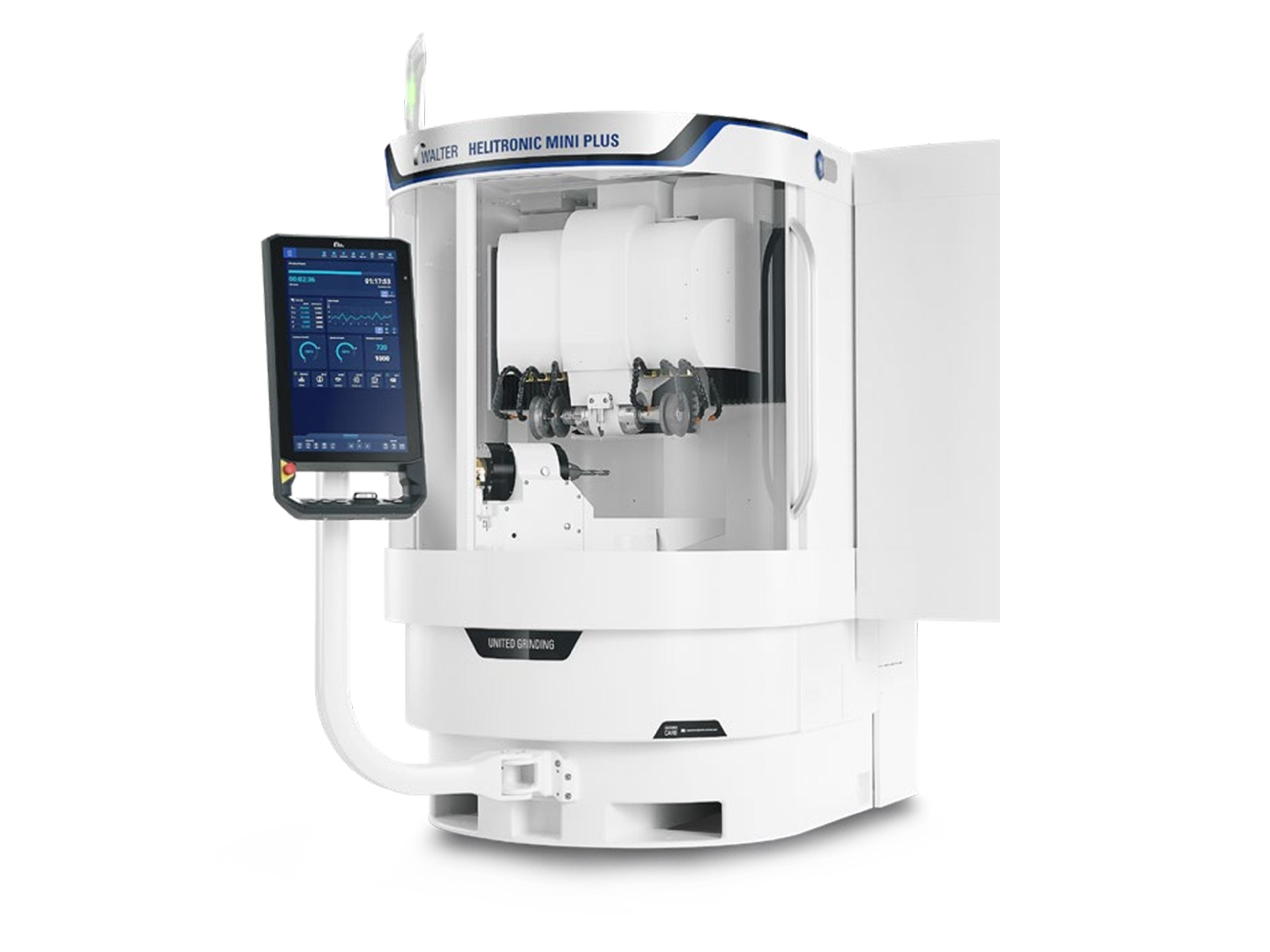

瓦尔特 HELITRONIC MINI PLUS

展商:United Grinding Group Management AG

原产国/地区:德国

HELITRONIC MINI PLUS 刀具磨床采用 C.O.R.E. 技术,特别适合中小直径刀具的灵活生产和重磨。不同的装载系统和效率选项使机床配置适合当前和未来的应用情况。结构紧凑,可充分利用生产车间空间。 The HELITRONIC MINI PLUS with C.O.R.E.-Technology is our new tool grinding machine for flexible production and resharpening of small and medium tool diameters. Various loading systems and efficiency options allow the machine to be configured to fit current and future applications. The compact design offers optimal utilization of floor space in production.

展品详情

具有两个主轴端的皮带驱动主轴

具有两个主轴端(标准)的高性能皮带驱动主轴最多可装备 6 片砂轮,最大功率为 9 kW。在该装备中,利用 HELITRONIC MINI PLUS 可以经济地制造中等批量大小的更复杂和常用的刀具几何形状(需要自动化选项)。各种砂轮组连同所有数据将被分配给主轴端。

激光轮廓检测(选项)

创新激光轮廓检测选项提供了一个智能测量系统,该系统直接集成在工具磨削和电解机床中,可对圆柱形工具上的各种工具参数进行高度准确、非接触式测量。

砂轮更换装置的机床扭矩增加(选件)

通过使用此选件,在最大转速为 7800 转/分钟时,HELITRONIC MINI PLUS 的扭矩和主轴的磨削功率会提高约 60%(与标准相比),因此可加工直径不超过 25 mm 的刀具。砂轮组的尺寸保持不变。

6 位自动砂轮更换装置(选件)

经济实惠,结构紧凑,机动灵活。最多可装备 6 套砂轮组,每套 3 片砂轮。最大砂轮直径为 152.4 mm。冷却液供应装置和砂轮组构成了一个整体。这确保了安全的砂轮组更换和最佳的冷却。

使用机器人装载机实现自动化(选项)

采用机器人能更方便地接近工件,满足特殊应用的需求。自动示教实现了较短的设置时间。根据工件类型或工件直径,通过机器人最多可装载 7500 个工件。最大工件重量为 5 kg;最大工件直径为 125 mm。

通过顶部装载机实现自动化(选件)

这个针对 HELITRONIC MINI PLUS 的自动化解决方案直接集成于加工区,它占地面积小且价廉物美。自动示教实现了较短的设置时间。根据刀具直径,顶部装载机可提供最多 500 个刀位。

Belt-driven spindle with two spindle ends

The powerful belt-driven spindle with two spindle ends can be equipped with up to six grinding wheels and has a peak power of max. 9 kW. In this configuration of the HELITRONIC MINI PLUS, both complex and common tool geometries can be produced economically in medium batch sizes (automation option is required). The various grinding wheel sets are allocated to the relevant spindle along with all data.

Laser Contour Check option

The new, innovative Laser Contour Check option offers an intelligent measuring system integrated directly in the tool grinding and eroding machine for the highly accurate, non-contact measurement of various tool parameters on cylindrical tools.

Torque increase option (only for machines with grinding wheel changer)

With this option, the torque and thus the removal rate at the spindle of the HELITRONIC MINI PLUS is spindle is increased by approx. 60 % (compared to the standard) at a max. speed of 7.800 min-1. This makes it possible to cut tools up to a diameter of 25 mm. The dimensions of the grinding wheel packs remain unchanged.

Automatic grinding wheel changer with 6 places (option)

Affordable, compact and flexible, too. With a capacity of up to 6 grinding wheel packs with 3 grinding wheels each. The max. grinding wheel diameter is 152.4 mm. Coolant supply and grinding wheel set form one unit. This ensures a safe change of the grinding wheel set and optimum cooling of the HELITRONIC MINI PLUS.

Robot loader automation option

The robot improves accessibility to the workpieces and makes special applications possible. Automatic teaching enables short setup times of the HELITRONIC MINI PLUS. Depending on the type of workpiece or the workpiece diameter, up to 7,500 workpieces can be loaded using the robot. Maximum workpiece weight 5 kg; maximum workpiece diameter 125 mm.

Top loader automation option

This space-saving and inexpensive automation solution is integrated directly into the machine envelope of the HELITRONIC MINI PLUS. Automatic teaching enables short setup times. Depending on the tool diameter, the Top loader offers a maximum of 500 places for tools.