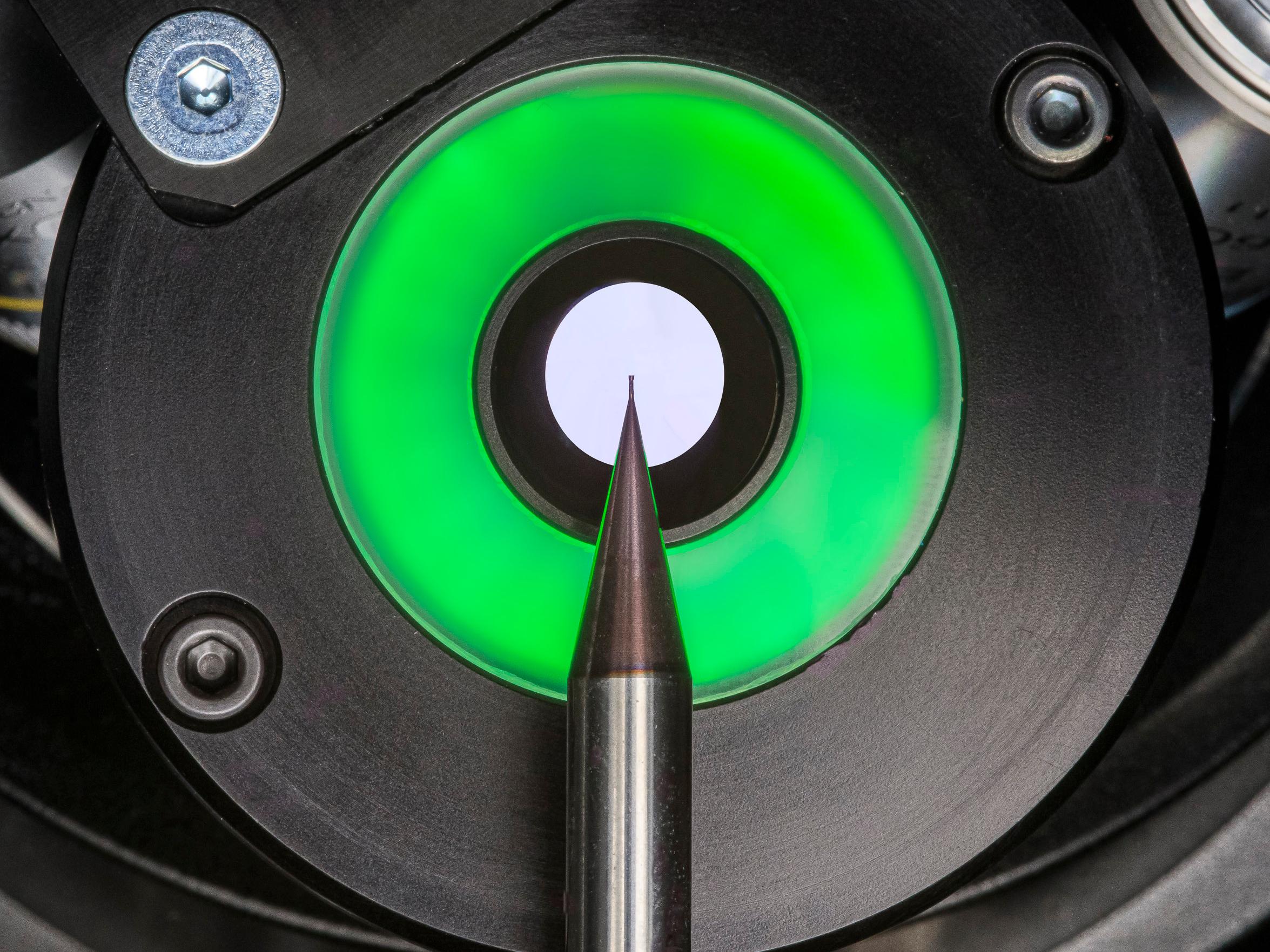

瓦尔特 HELICHECK NANO

展商:United Grinding Group Management AG

原产国/地区:德国

对于微观和纳米范围内复杂几何形状的全自动完整测量,HELICHECK NANO 数控测量机是比较理想的解决方案。使用显微镜传感器甚至可以可靠地测量和分析直径 0.1 毫米自起的最小几何形状。HELICHECK NANO 可在直径不超过 16 毫米的范围内充分发挥其优势。凭借经过认证的精度,其为现代化工具生产的效率、质量和精度树立了标杆。在全自动工具加工中,利用集成的公差补偿机制,同步实现了关键的“质量控制”功能。 For the fully automatic complete measurement of complex geometries, the HELICHECK NANO CNC measuring machine in the micro and nano range is the ideal solution. Thanks to the microscopic sensor technology, even the smallest geometries can be reliably recorded and evaluated - from a diameter of 0.1 mm. In the range up to 16 mm diameter, the HELICHECK NANO shows its strengths to the full. With certified accuracy, it sets standards for ensuring productivity, quality and precision in modern tool production. In automated tool machining, it assumes the key function of "quality control" with integrated tolerance compensation in the process.

展品详情

稳固的大理石床身

稳固的大理石床身凭借着其很重的重量为精密性和精确度奠定了基础。它具有减震缓冲性能,并具有很高的热稳定性。这些是 HELICHECK NANO 达到最高测量精度并确保测量结果可靠的先决条件。

参照值 EUX,MPE

对于HELICHECK NANO,允许的测量偏差范围为 EUX,MPE = (1.2 + L/300)。

ISO 50 主轴

高精度 ISO 50 主轴配备自动夹紧机构,可保证通过 HELICHECK NANO 实现精密及可精确重复的测量。

经认证的精度

按照 VDI/VDE 2617 标准要在不同的时间间隔采用经认证的标准件通过不同的测量对测量机的精度进行评价。为此,WALTER 使用经认证的阶梯塞规和角度规,以提高精度。按照标准要至少进行三次测量。WALTER 对这些测量分别进行十次。联邦技术物理研究所出具的校准证书对量规的高精度进行了认证。

Solid granite base

A solid granite base provides the basis for precision and accuracy due to its weight. This granite base provides vibration damping and is thermally stable. These are the prerequisites for the highest measuring accuracy and reliable measuring results of the HELICHECK NANO.

EUX,MPE value

On our HELICHECK NANO measuring machine, the EUX,MPE value is (1.2+L/300)µm as standard.

ISO 50 spindle

The high-precision ISO 50 spindle with automatic clamping mechanism ensures precise and repeatable measurements with the HELICHECK NANO.

Certified accuracy

According to VDI/VDE 2617, the accuracy of a measuring machine is evaluated by various measurements at different intervals on a certified calibration standard. WALTER uses a certified plug gauge or optionally a glass scale for increased accuracy. According to the standard, at least three measurements are required. WALTER performs ten measurements. The calibration certificate from the Physikalisch-Technische Bundesanstalt certifies the high accuracy of the glass scale.