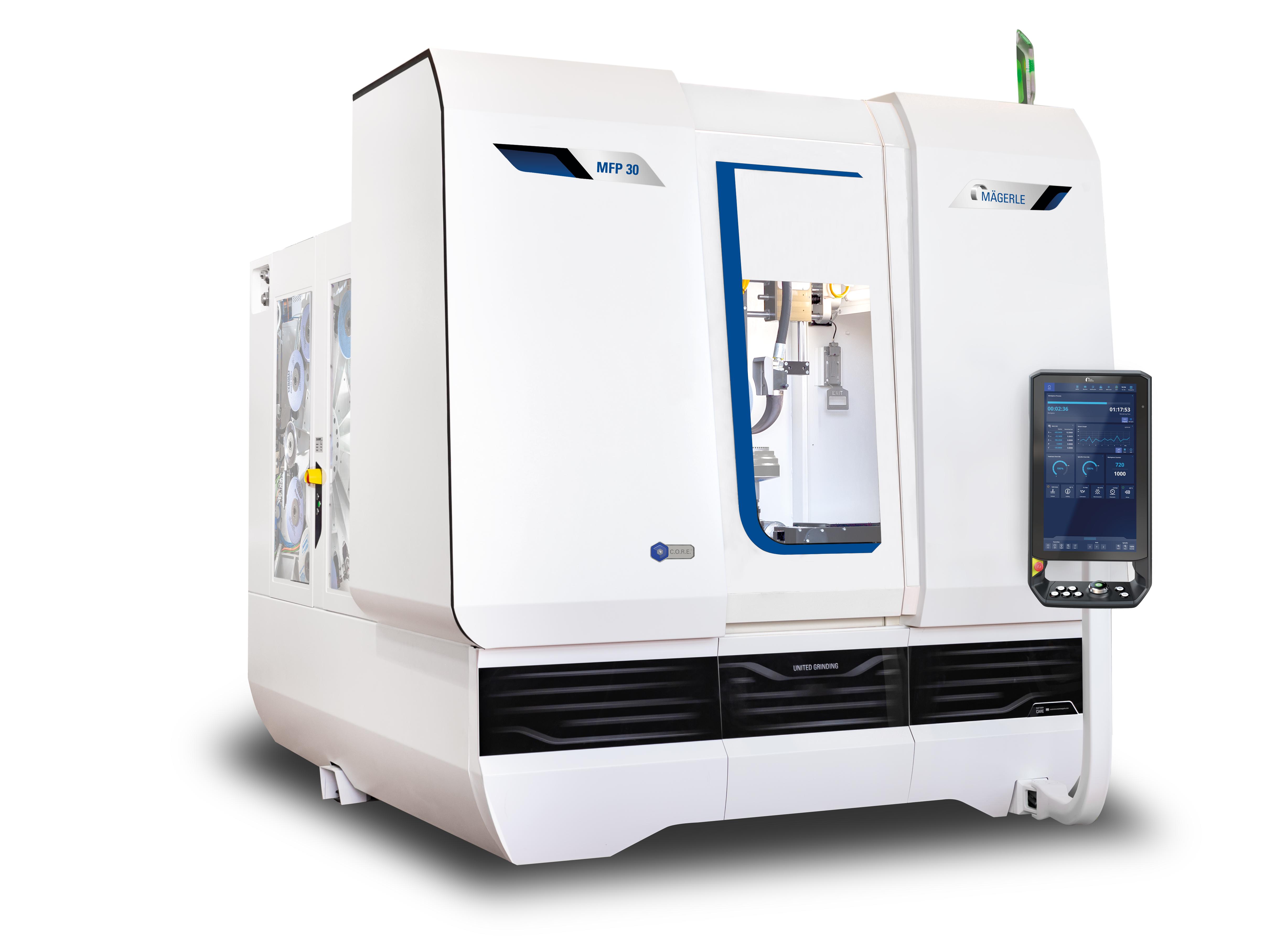

美盖勒 MFP 30

展商:United Grinding Group Management AG

原产国/地区:瑞士

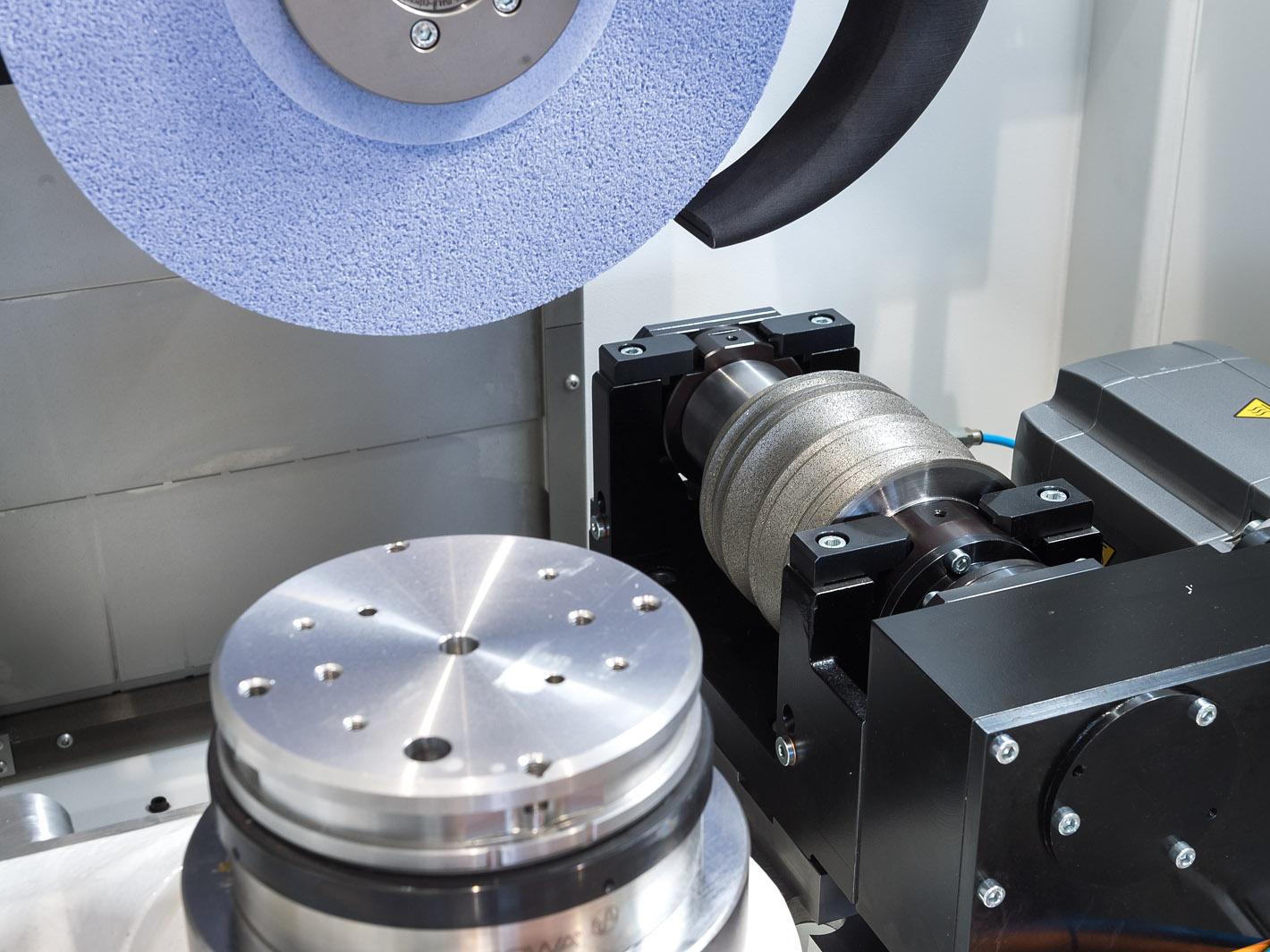

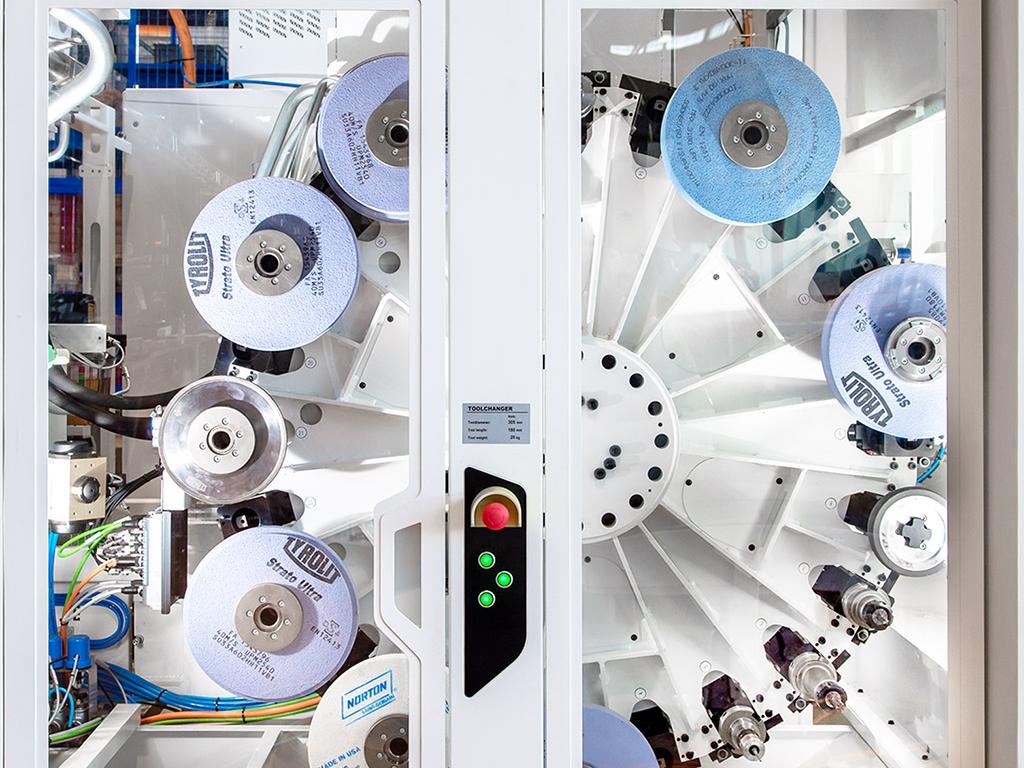

MFP 30五轴平面成型磨床是磨削复杂几何形状工件的理想选择,例如飞机发动机导向器叶片、涡轮叶片或围带类零件等。 待加工的工件直接从前面装入工作区域,符合人体工程学。 带夹具的重型工件可以用起重机从上面装载。 MFP 30五轴平面成型磨床紧凑而又节省空间的设计可优化使用现有生产区域,并实现有效的生产流程。 MFP 30, the compact 5 axis grinder is ideal for grinding complex geometries, particularly in the case of guide and rotor blades as well as heat shields for aircraft turbines. The workpieces to be machined are loaded ergonomically directly from the front into the working space. Heavy workpieces with a suspension device can be loaded from the top with a crane. The compact and space-saving design allows optimal use of the existing production area and enables effective production flow.

展品详情

高性能和高扭矩

高性能主轴的强大驱动允许各种磨削工艺的组合,如用刚玉砂轮的大切深磨削或用CBN砂轮的磨削。即使在低转速区间,也可提供较大的功率和高扭矩。通过坚固的工具夹具,可以实现宽轮廓的加工,并具有高材料去除率。磨削过程可以用乳化液或磨削油完成。高性能主轴的高转速区域为工件在一次装夹下的要求苛刻的磨削工序提供了最佳的加工条件。

工艺优化的冷却液供应

通过双轴控制喷嘴提供最佳的冷却液供应。对于磨头箱主轴两侧的喷嘴也可加工提供冷却液。

通过集成的砂轮清洁系统,在磨削过程中砂轮保持更清洁和锋利,使用的时间更长。这提高了材料去除率,同时减少了砂轮的消耗。

High efficiency and high torque

The high performance spindle drive enables the combination of different grinding processes, such as creep feed grinding with corundum or CBN grinding. Even at low speeds, full power and high torque remain available. The robust tool holding fixture allow wide machining contours to be realized at high removal rates. The grinding process can be performed with emulsion or oil. The high speed spindle provides optimal machining conditions for challenging grinding and milling processes in one clamping.

Process optimized coolant supply

The 2-axis controlled coolant nozzle enables an optimal coolant supply to the tool or workpiece. Nozzles are available on the grinding support for drilling and milling tools, and a coolant supply can be provided through the spindle.

Thanks to integrated grinding wheel cleaning, the grinding wheel remains clean and sharp for longer periods during grinding. This increases the removal rates while reducing the grinding wheel wear.