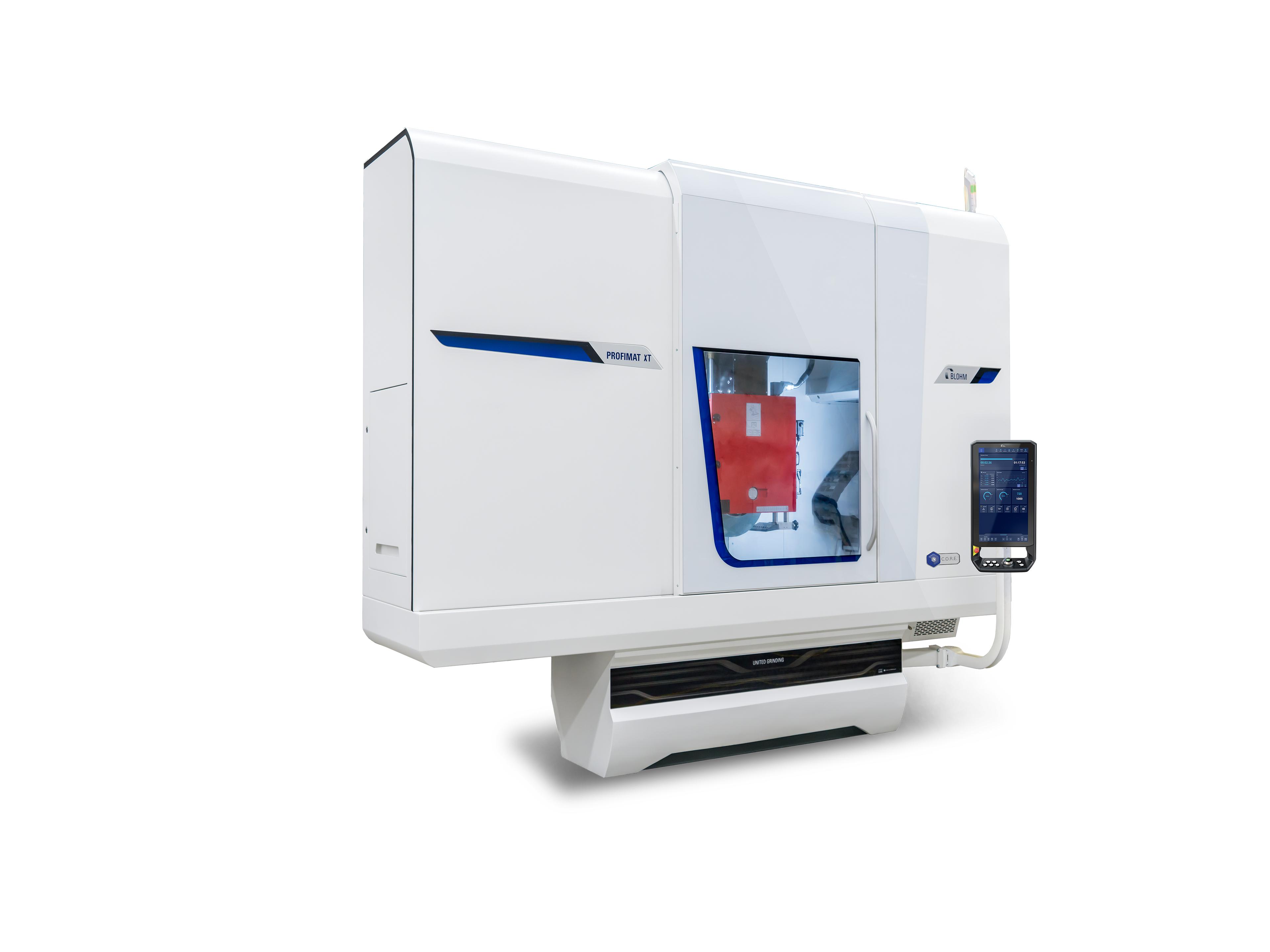

保宁 PROFIMAT XT

展商:United Grinding Group Management AG

原产国/地区:德国

为满足日常生产和灵活技术应用的不同需求,Blohm开发了PROFIMAT XT。 灵活的配置选项结合PROFIMAT XT(尺寸从400x800 到 600x2000毫米)的模块化系统,可以为各种生产环境和行业提供业界领先的解决方案。可用于转向螺母、扇齿轴、摇臂、涡轮叶片等零件的磨削加工。 To meet the different demands of everyday production and for flexible technological applications, Blohm developed PROFIMAT XT. The comprehensive range of accessories combined with the modular PROFIMAT XT system (sizes from 400x800 to 600x2000mm) can provide an industry-leading solution for a wide variety of production environments and industries. It can be used for grinding and processing work pieces such as piston rack nut, sector shaft, Rocker arms, blade and so on.

展品详情

更高的运动轴快移,更高的加速度和更高的系统刚性 - 这些改进的影响因素的结合带来生产率和加工零件质量的提高。 这些特性是基于非常成功的PROFIMAT MT的经验和质量控制,使PROFIMAT XT成为稳定而强大的生产型磨削机床。

除了高质量的机器元件,如直线电机驱动,优质球墨铸铁和精密预载型线性导轨,新一代机床为操作人员提供了一个全新的用户界面。 由三部分组成的显示触屏面板供可单独调节的屏幕区域。 与所需工作步骤相关的信息可以以定制的方式进行编程和检索。 这里提供的可能范围包括工件绘图、3D模型、操作手册和原理图以及GripsProfile—由 Blohm 开发的用于砂轮轮廓成型的编程系统。 该区域还可提供符合工业4.0的可视化冷却过滤系统状态和过程监控显示。

Higher main axis speeds, greater acceleration and increased system rigidity - the combination of these consistently optimized essential performance characteristics means increased productivity while improving component quality. These features distinguish the PROFIMAT XT as a robust and effective production grinding machine that consistently builds on the experience and quality of the highly successful PROFIMAT MT.

In addition to high-quality machine elements such as ground ball linear drive, optimized ductile cast iron and precision guidelines, this generation offers the operator a completely new user interface. The three-part control panel now offers customizable screen areas. The information relevant to the required work steps can be programmed and retrieved for the specific customer. The possibilities offered here range from component diagrams, 3D models, user manuals and electric diagrams to GripsProfile, Blohm's proprietary programming system for profiling of grinding wheels. This area also offers the possibility to call up screens for coolant, statuses and process monitoring based on the Industry 4.0 concept.