展品详情

A global pioneer in inline spectroscopic technology, dedicated to providing unparalleled solutions for process monitoring, control, and automation, especially designed for extrusion processes. As an industry leader, we are committed to driving innovation and excellence across a range of sectors, including polymers and plastics, recycling (mechanical, chemical, PCR, industrial), pharmaceuticals (PAT for HME), chemicals, paints and coatings, and food production.

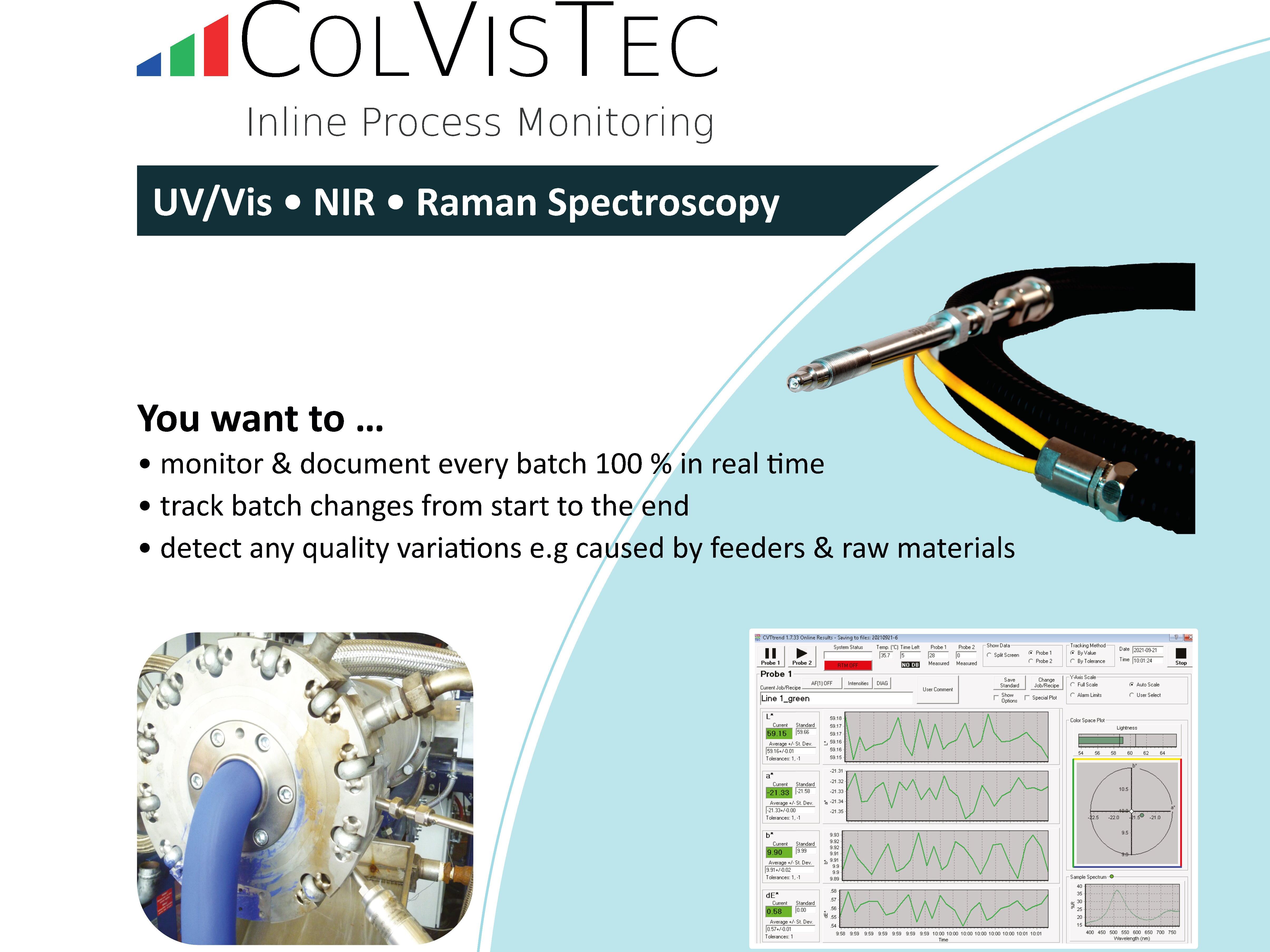

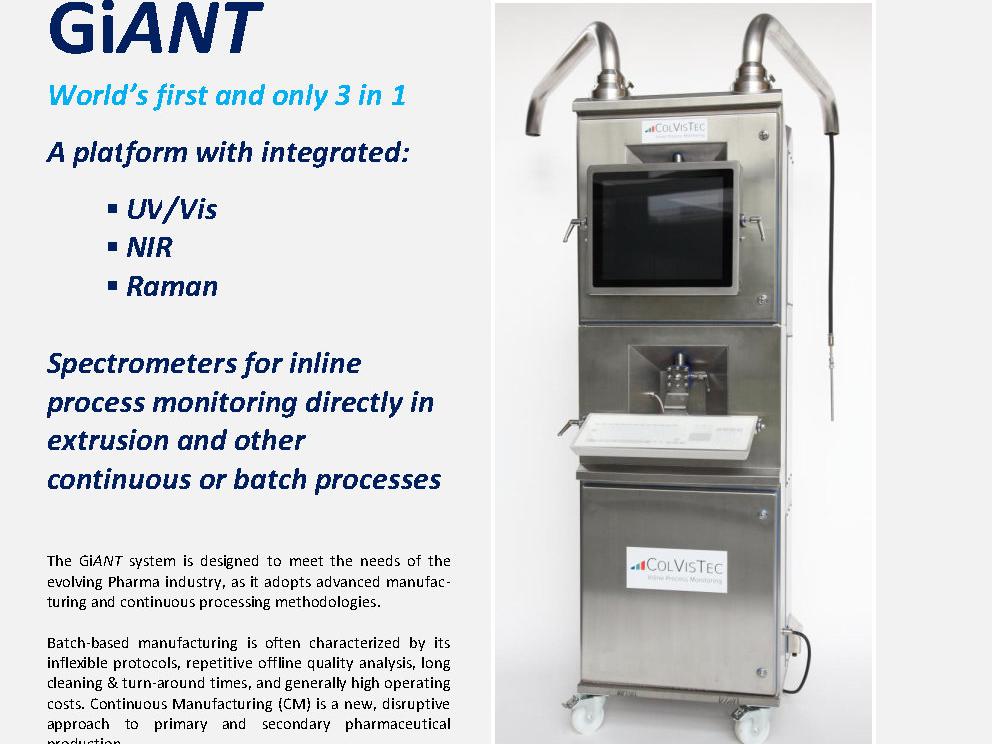

Our advanced inline technologies, including UV/Vis, NIR, and Raman spectroscopy systems, are designed to deliver comprehensive insights into your processes, enabling you to optimize efficiency and maintain the highest standards of quality. By harnessing the power of real-time data and 24/7 precision monitoring, our technology helps you stay ahead of the competition, reduce waste, and enhance overall operational performance.

At ColVisTec, we focus on advanced technology that addresses both current needs and future challenges. We are committed to continuous improvement and innovation, providing tools that optimize your processes and ensure peak performance with clear insights into process and product quality.

Working with ColVisTec means accessing top-notch technology and expert support. We help you navigate modern manufacturing complexities and achieve greater success.

Discover how ColVisTec’s spectroscopic technology can enhance your processes, improve efficiency, and strengthen your industry position. Join the many companies worldwide that trust our expertise and take the first step toward a more efficient future.

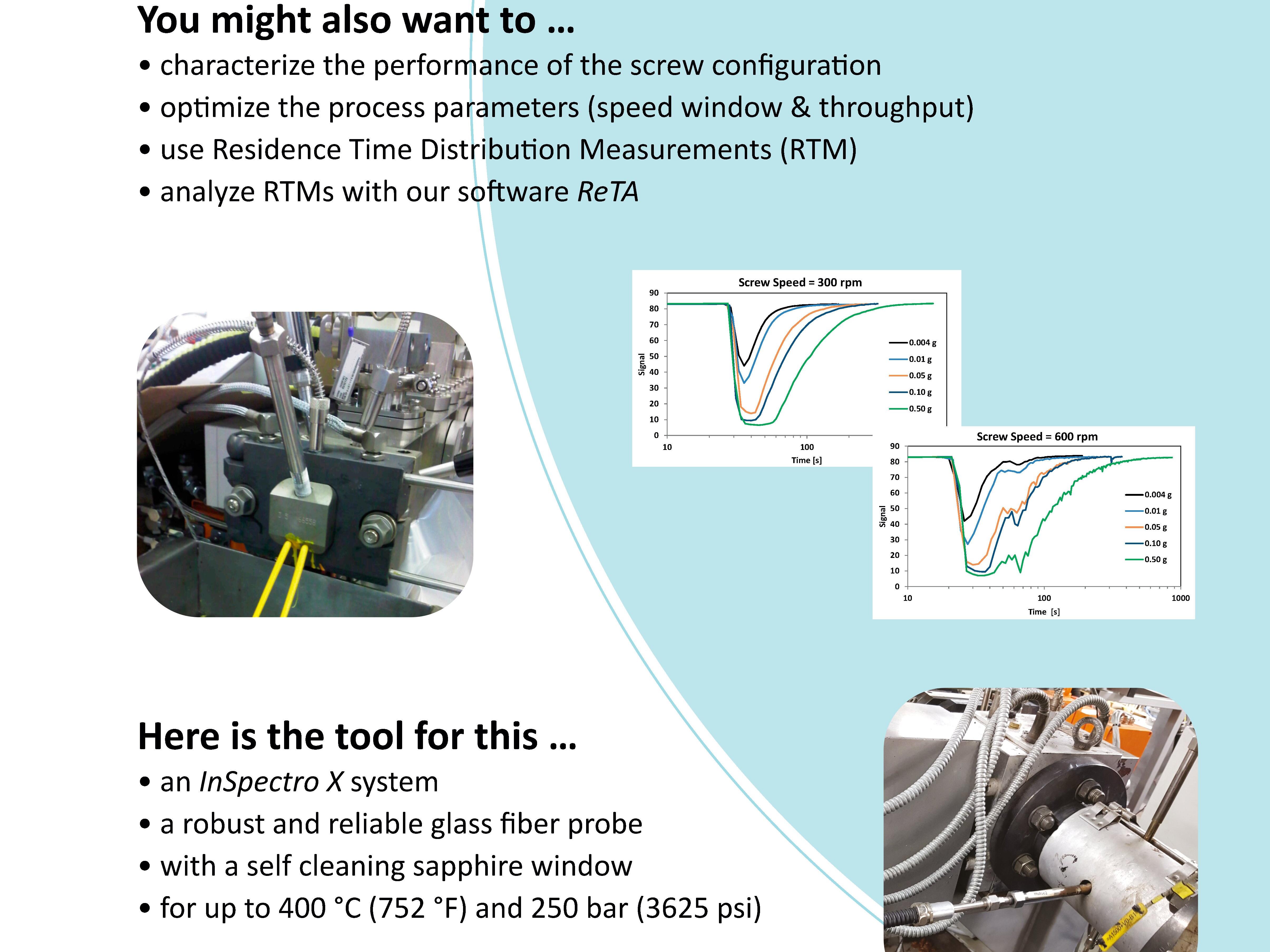

The InSpectro X was designed as an inline color measurement system for continuous production processes. It comprises an integrated spectrometer, which can simultaneously evaluate measurement signals from up to two probes in the wavelength range of 220 - 820 nm, in 1 nm steps. For many applications, the complex spectral information can be divided into three simple color values, e.g. L*, a*, and b*. These are automatically converted from the CIELab color space and displayed. These reduced color values serve as real-time indicators for an ongoing process.

With the InSpectro X, it is possible to obtain information at points or locations in the process from which no measurements were previously possible. The technology is compatible with a wide range of materials, melts (e.g., plastics, pharmaceuticals), liquids (e.g., paints, inks) and powders in blending operations.

In combination with the fiber optics RPMP and TPMP our devices can be used to measure in reflection and in transmission modes.